How to Choose the Best Flexible Packaging Film for Your Needs?

In today's rapidly evolving packaging landscape, selecting the right Flexible Packaging Film is crucial for manufacturers. According to a report by Smithers Pira, the flexible packaging market is expected to reach $400 billion by 2025. This growth indicates not only increased demand but also the necessity for informed decision-making. Industry expert Dr. Jane Anderson, known for her work in sustainable packaging solutions, states, "Choosing the right film can make or break a product's success."

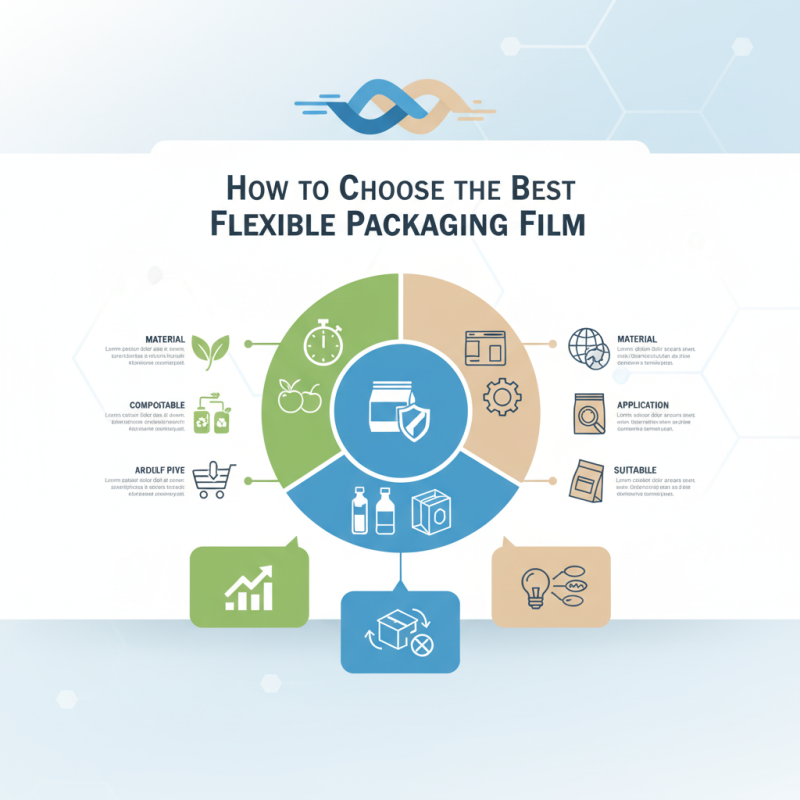

Various factors come into play when selecting Flexible Packaging Film. These include material choice, environmental impact, and application suitability. A poorly chosen film can lead to product spoilage, increased waste, or unmet consumer expectations. The choices can be overwhelming, especially with advancements in technology and materials. Companies must reflect on their needs and potential pitfalls in their selection process.

Flexibility in packaging is not just about the material; it also involves adapting to market trends. Trends such as sustainability and convenience are shaping consumer preferences. As companies strive to align their packaging with these trends, thoughtful evaluation of Flexible Packaging Film becomes more important than ever.

Understanding the Different Types of Flexible Packaging Films

When selecting flexible packaging films, understanding the different types is crucial. Flexible films come in various materials, such as polyethylene, polypropylene, and laminates. These materials serve distinct purposes. For instance, polyethylene is commonly used for moisture barrier applications, while polypropylene offers a higher resistance to heat.

Recent industry reports indicate that the flexible packaging market is projected to grow by approximately 4.5% annually until 2028. This growth is driven by increasing consumer demand for convenience. However, choosing the right film can feel overwhelming. Many users struggle with specifications like thickness and durability. The right thickness impacts the film's strength and the product's shelf life.

Some reports highlight challenges with waste management in flexible packaging. Around 30% of consumers express concern over recyclability. This raises questions about the long-term sustainability of certain films. Brands must not only focus on functionality but also consider environmental impact. Understanding these nuances can aid in making informed decisions.

Key Factors to Consider When Choosing Flexible Packaging Films

When choosing flexible packaging films, several key factors demand your attention. Consider the type of product you are packaging. Is it food, cosmetics, or electronics? Each category has different requirements. Barrier properties are crucial for food safety. Packaging films must prevent moisture and oxygen from spoiling contents. For cosmetics, UV protection can be vital. Understanding your product's specific needs is essential.

Next, think about the film's structural integrity. It should withstand handling and transport. Tears or rips can compromise your products. Choose a film that provides durability and puncture resistance. You may also want to reflect on how the film interacts with printing. Will your design stand out? Vibrant colors and clear graphics can enhance shelf appeal.

Lastly, consider environmental impact. Biodegradable options are emerging yet often come with drawbacks. They may not always meet mechanical strength requirements. Reflect on your sustainability goals versus product protection. Achieving a balance can be challenging but necessary.

Evaluating Performance Characteristics of Flexible Packaging Materials

When selecting flexible packaging film, performance characteristics are crucial. Consider the material's barrier properties. A good film should protect contents from moisture, oxygen, and light. This extends shelf life and maintains quality. Look for films that match the specific needs of your product, such as food or pharmaceuticals.

Tips: Always test the film with your product prototype. This ensures compatibility and allows you to assess its performance. Consider temperature resistance too. Films may behave differently under heat or cold. They must withstand shipping and storage conditions.

Durability is another aspect to evaluate. Films should resist punctures and tears. This is particularly important for items that face rough handling. Remember, not all films are created equal. Some may perform well under certain conditions but fail under others. Regular testing and feedback can help improve your choices.

Sustainability and Environmental Impact of Flexible Packaging Options

Flexible packaging has gained traction in recent years due to its versatility and efficiency. However, the sustainability aspect of this packaging solution is often questioned. According to a report by the Flexible Packaging Association, flexible packaging can reduce waste by 70% compared to rigid packaging. This statistic highlights a significant advantage. Yet, it prompts reflection on how materials are sourced and disposed of.

Biodegradability is a critical concern. Many flexible films currently on the market are not biodegradable, leading to increased landfill waste. The Ellen MacArthur Foundation estimates that only 14% of plastic packaging is collected for recycling globally. Consumers are increasingly demanding better solutions. They seek materials that minimize environmental impact while maximizing product protection.

Innovative materials such as biodegradable films show promise. However, they still require further development and widespread adoption. Balancing functionality with environmental consciousness is essential. Recognizing that all options have trade-offs is crucial. Investing in research can lead to better alternatives that meet both consumer needs and sustainability goals.

Cost Considerations in Flexible Packaging Film Selection

Choosing the right flexible packaging film can significantly impact your production costs and efficiency. One of the primary factors to consider is the cost of materials. According to the Flexible Packaging Association, raw material costs can account for up to 60% of the total cost of packaging. Thus, understanding market trends is vital to make informed decisions.

Tips: Always evaluate multiple suppliers to compare prices. Look for bulk purchase discounts or special offers that could lower the overall cost.

Another aspect to consider is the total life cycle cost. While cheaper options are appealing, they may not perform as well. Poor barrier properties can lead to product spoilage, which can be costly. A report from Smithers Pira states that switching to a high-performance film can reduce waste by up to 30%.

Tips: Invest in quality materials. It’s often more economical in the long run, even if the upfront cost is higher. Analyze your specific needs to avoid overpaying for unnecessary features.

How to Choose the Best Flexible Packaging Film for Your Needs? - Cost Considerations in Flexible Packaging Film Selection

| Film Type | Material Cost ($/kg) | Barrier Properties | Application | Estimated Lifespan (Months) |

|---|---|---|---|---|

| LLDPE (Linear Low-Density Polyethylene) | 2.5 | Good | Flexible Pouches | 12 |

| PET (Polyethylene Terephthalate) | 3.0 | Excellent | Snack Foods | 18 |

| BOPP (Biaxially Oriented Polypropylene) | 2.8 | Good | Dry Foods | 24 |

| PVC (Polyvinyl Chloride) | 2.2 | Moderate | Medical Packaging | 6 |